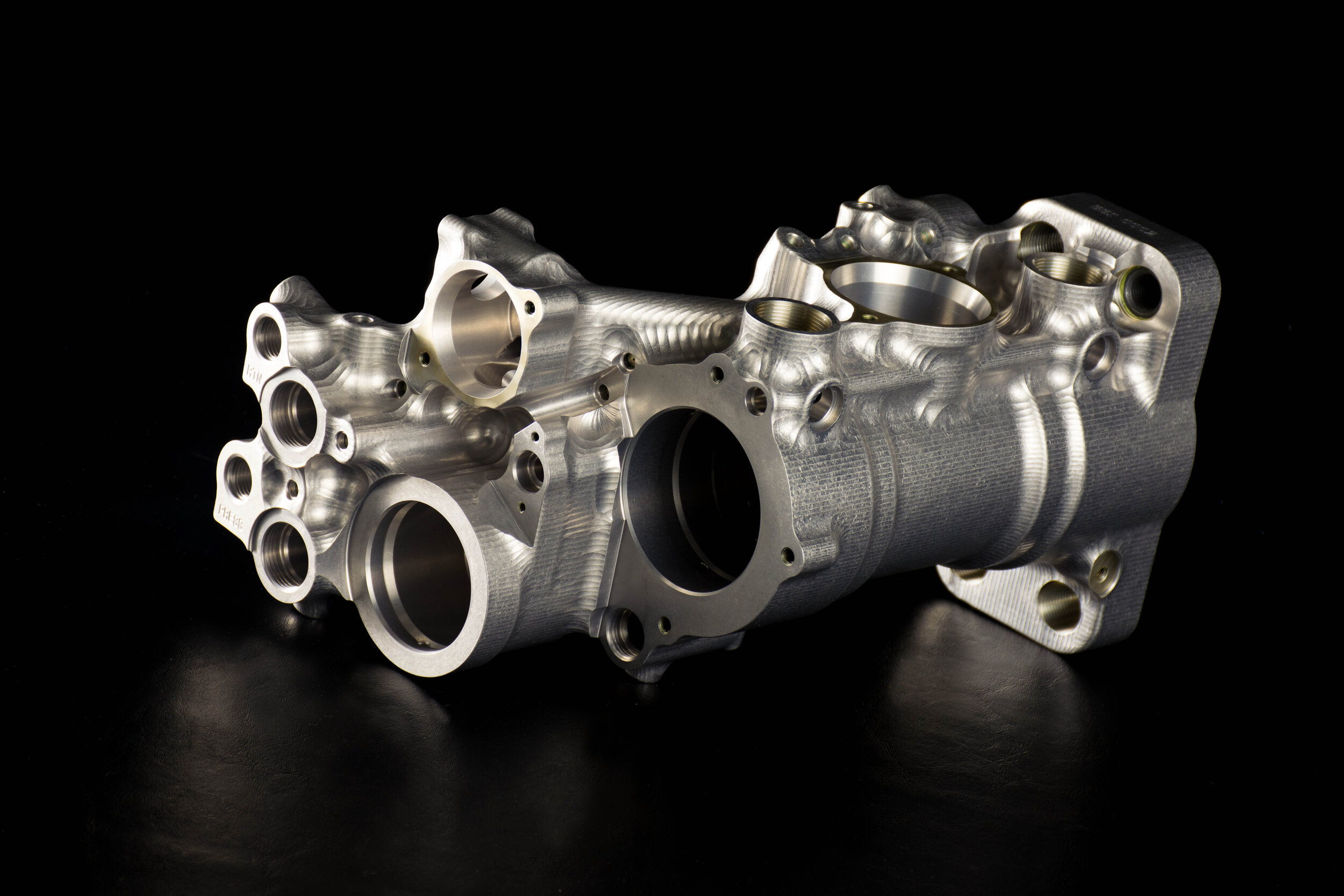

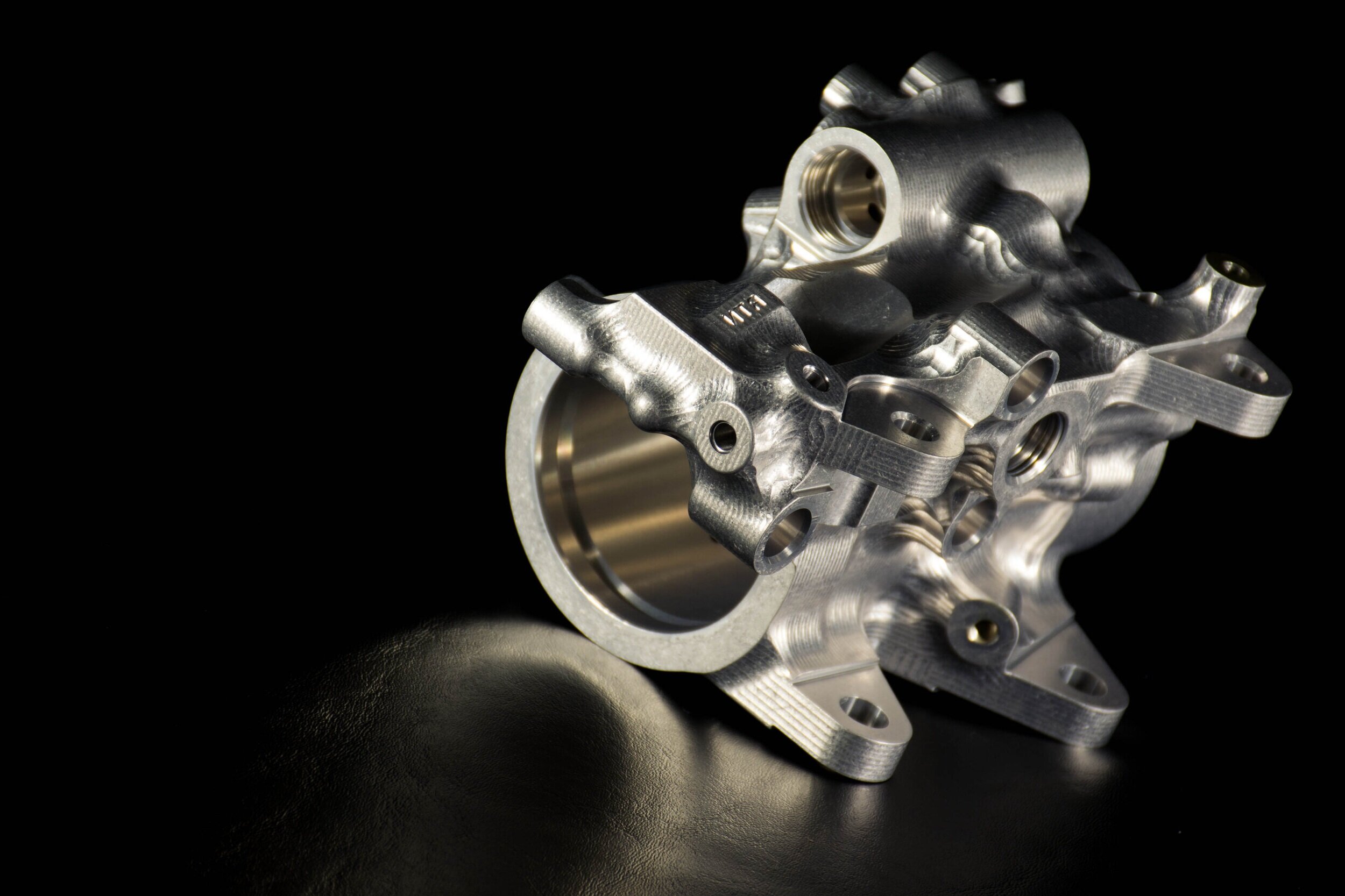

your partner for complex product development

Since 1989, BBI has enjoyed steady growth in operations and long lasting customer relationships. Our consistent investment in the latest technologies and training provide a unique experience with our customers, while servicing a diverse range of leading industries.

As we continue to grow with every opportunity, we offer unmatched quality and expertise in precision manufacturing. We seek to diversify and expand our business into many different markets both local and internationally.

Located in Fridley, MN, in close proximity of the Twin Cities area, BBI’s facility is operated by over 130 dedicated, highly-skilled employees. We understand the pressing needs our clients have for precise, prompt attention to the parts that keep their businesses running. BBI uses its own internal sales, engineering, production, quality, assembly and shipping departments to work with our clients every step of the way.

QUALITY WINS!

BBI has a hard-earned reputation for quality, expertise and complete customer satisfaction.

Quality programs

AS 9100D Certified

11 DCC CMMs - Travel up to 32” x 36” x 28”

General company information

Operation Hours: 6am-5pm/Office Hours: 8am-5pm

Machining Capacity: Over 75 CNC Machine Tools

100,000 sq. ft. in Main Building